Measuring devices

© ProZa Messsysteme 2025

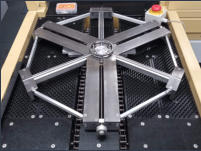

Fully automatic

- Post process measuring

machine for testing shafts and

axles

The system is customer-specifically

designed for simultaneous testing of six

diameters in a range of min. 20h6 and

max. 50h6, with a maximum part length

of 150mm. Automatic machine

adjustment based on individual,

average, or moving average values, as

well as customer-specific values, is

possible. Changeover takes less than 3

minutes.

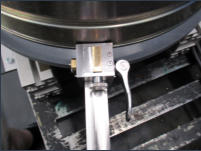

- Post process measuring

machine for testing disc-shaped

rotationally symmetrical parts.

Designed for a range of approximately

160 similar parts. Two inner diameters

from 17mm to 140mm and two outer

diameters from 40mm to 300mm can be

tested. The inner diameter can be freely

positioned within the 17-140mm range

using a crank, and the height is

adjustable via 7 stops. The outer

diameter can be set in 13 positions

within the 40-300mm range and in 7

height positions. The workpiece is

mounted on a three-point support and

secured in a three-jaw chuck. Manual

changeover - changeover time < 5

minutes. Dimension determination via 2-

point measurement using 12mm

incremental probes. Automatic machine

adjustment based on individual values,

average values, or moving average

values, as well as customer-specific

values.

- Post-process measuring

machine for brake drums

Designed for simultaneous testing of

two inside diameters. The system is

configured for a customer-specific range

of two parts. No conversion is required,

as the range of parts is within the stroke

range of the probes and the chuck.

Simultaneous testing of two inside

diameters. Measurement values are

recorded via incremental probes.

Automatic machine adjustment based

on individual, average, or moving

average values, as well as customer-

specific values.

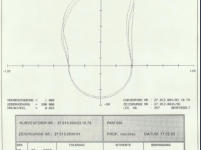

- Polar coordinate measuring

machine

For testing cams or cam-like parts with

a maximum diameter of 600 mm.

Measurement and evaluation time with

target and actual comparison and

adjustment < = 30 seconds.

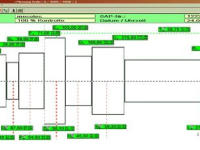

Fully automatic

- Fully automatic measuring

device with robot.

100% inspection - 100% quality. Cycle

time < 20 seconds. Due to the

increased division of labor in production

processes, e.g., through outsourcing,

interfaces are created whose

functionality and documentation must

be ensured. 100% quality of the

incoming parts is essential, especially in

fully automated assembly lines. Robotic

inspection devices are used to reduce

production costs. Measurements are

recorded using electronic probes or

non-contact lasers in the µm range. The

measured values are evaluated by the

MCQ 2000 measuring computer. The

query speed is < 1 msec., the

measurement resolution is 0.1 µm.

Pass/fail statements are displayed, and

classification or sorting is performed.

The recorded measurement data can be

evaluated internally and/or transferred

to higher-level CAQ systems for

statistical analysis. The mobile system

can also be connected to LANs.

- Shaft measuring machine

In response to increasing customer

demands for greater transparency in

quality management and the associated

traceability of measurement results in

parts production, we have developed

and built automatic measuring

machines for well-known manufacturers

of shaft-shaped parts. These automatic

measuring machines are capable of

measuring a range of parts, such as

gear shafts, drive shafts and camshafts,

without the need for extensive

modifications or adaptations to the

measuring machine. This means you

can guarantee the quality of your

production quickly and close to the

process, as well as saving expensive

coordinate measuring machine time.

Length, diameter, distance dimensions

and cam angle can currently be

determined on parts 100-1000mm long

and weighing up to approx. 30 kg. The

measuring machine is designed so that

it can be used without any problems in

the production area of a forge. The

operator only has to place the test piece

into a loading prism and start the

measuring sequence.

All actions required for measurement

are performed independently by the

measuring machine. It is designed as a

compact system (W x D x H 2000 x

1200 x 2000) and protected from dirt

and unauthorized access by sheet

metal cladding. The measurement data

is recorded by a laser and several

incremental measuring systems

connected to an MCQ 2000+ measuring

computer and presented to the operator

as numerical and/or graphical values on

the display. The results can be

statistically evaluated and/or saved, or

further processed online.

Semi-automatic

- Funkbox

FTB 200 The wireless box transmits

an inductive probe value and a temperature

sensor value (Li-ion) via radio

from a battery-powered transmitter to

a receiver box or measuring computer.

Three function buttons, "Measure,"

"Calibrate," and "Temperature Transfer,"

are also transmitted to the receiver box.

The probe value and the temperature

value are output in the receiver box as

two analog values at standard sockets or

processed directly in the computer.

The three "function buttons" are available

on the receiver box as three potential-free

digital outputs, optionally for processing in

the measuring computer.

The wireless box is designed so

that it can be easily clamped to

a measuring bar, making operation much

easier. It can be operated with one finger,

leaving both hands free to guide the

measuring bar.

The radio box features an integrated LCD

display (low-power version, 2 lines of 16

characters each, optional graphic display

with measuring column display).

Five values are available to the operator

on this display as standard: measuring

time, battery voltage with low battery

warning, the measured value of the

inductive probe (+- 2000; +- 200.0 µm),

the temperature value of the sensor

(or, if the sensor is not plugged in, the

temperature at the box), as well as the

coded active function key and an indicator

"Radio connection OK."

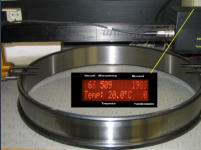

Tempering plates for Calibration

master

The tempering plates are used for

thermal stabilization and adjustment of

the Calibration master to the workpiece.

We offer a standard range from 150 to

500 mm, but we also manufacture

tempering plates according to customer

specifications.